HUV Printing:

Elevate Your Prints with High-Speed, High-Quality Technology

Offset printing has been widely used in commercial printing due to its fast printing speed, low cost, high image clarity, and excellent color reproduction since its inception.

In Artron's art and photography printing projects, which have the highest requirements for image quality and texture, HUV printing is frequently adopted.

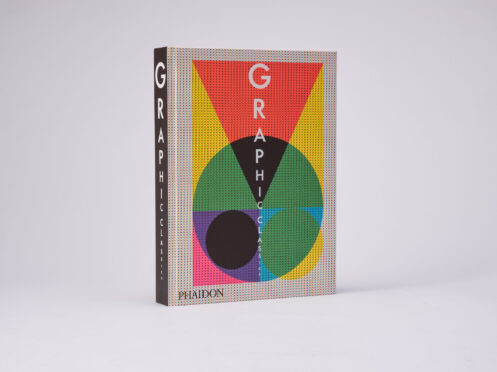

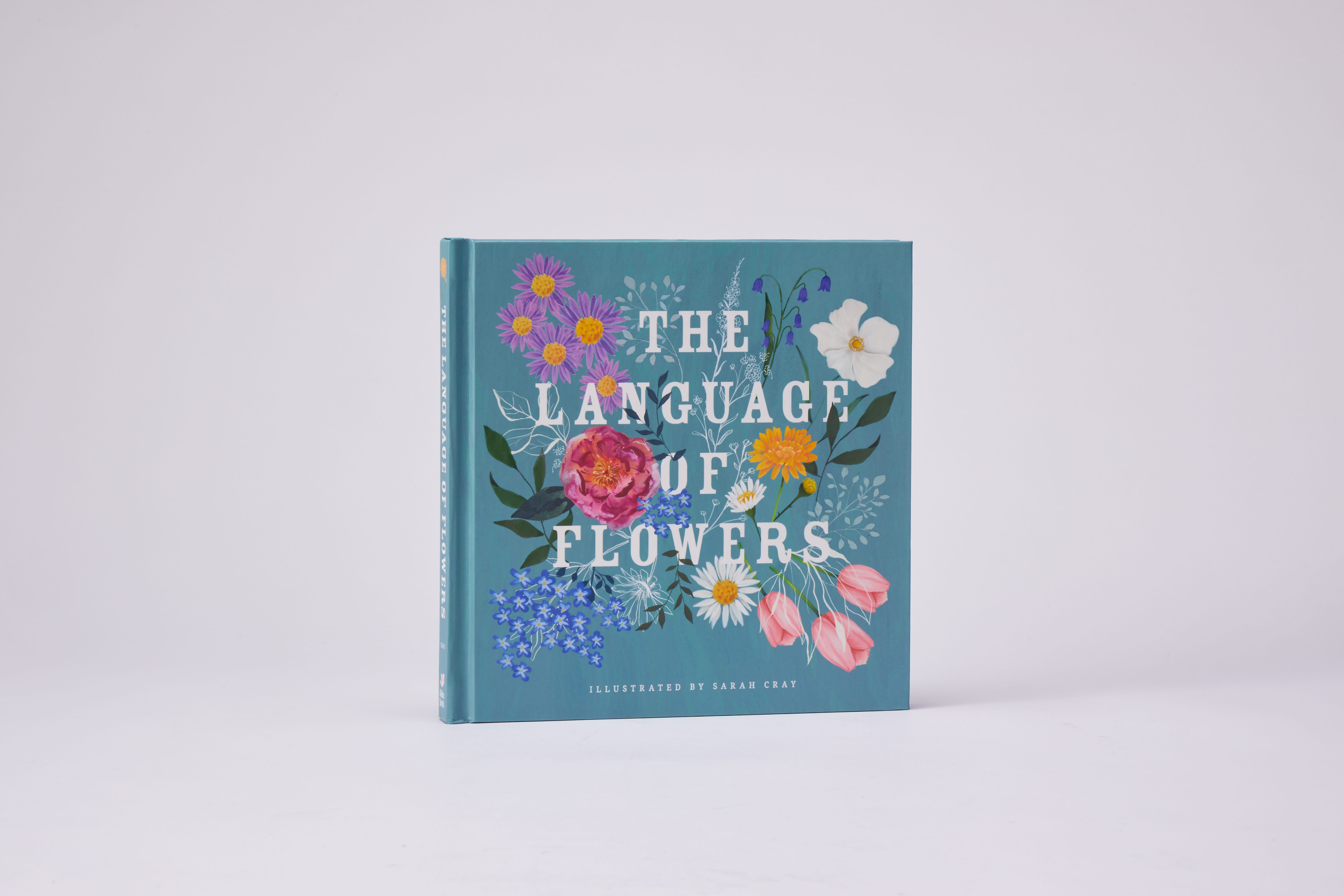

Following two printed works all used HUV Printing.

So, what is HUV printing? How does it differ from offset printing? Why do publishers like Phaidon Press, which specializes in high-end coffee table books, choose HUV printing?

What is HUV Printing?

HUV (High Ultra Violet) printing technology emerged in the printing industry around 2012-2013. The most distinctive feature of HUV offset printing is its ability to instantly dry ink after printing, partially solving the drying problems of specific inks. HUV printing can be described as digital offset printing: it combines the low cost of offset presses with the fine detail of digital printing, while retaining the charm of traditional printing techniques.

What are the Benefits of HUV Printing?

HUV printing is favored by offset printers due to its high efficiency in mass production. Its goal is to optimize the productivity of printing plants. In fact, unlike UV printing, HUV printing enables instant drying of sheets, significantly improving production efficiency by shortening the production cycle. Sheets coming off the press are ready for immediate finishing!

Furthermore, HUV printing offers numerous advantages: higher color saturation thanks to unmatched print density; shorter production cycles and fewer smudging issues due to instant drying; and a wider range of printable substrates such as kraft paper, tracing paper, high-grammage creative papers, and plastics, which was unimaginable in traditional printing.

Environmental Impact of

HUV Printing

In the printing industry, "being eco-friendly" means not only using PEFC, FSC, or recycled paper but also being responsible for the use of electricity, inks, and waste recycling.

HUV printing reduces energy consumption, resource usage, and carbon dioxide emissions. In fact, compared to standard presses, ozone and carbon dioxide emissions are reduced by nearly 25%. Additionally, its lamps are less costly and consume less energy. Finally, as protective varnish is no longer needed, the substrate is not denatured. Since the process eliminates the need for drying and anti-offset powders, the working environment is significantly improved with less smell in the workshop and better overall air quality.

Artron Printing and HUV Technology

As you can see, HUV printing offers:

- High quality and reliability

- Excellent economic performance

- Significant environmental benefits

Artron Printing has been committed to exceeding your expectations in print quality since its inception. With HUV printing technology, we guarantee to provide you with the best quality service that meets your needs. Artron Printing has a strong technical background in color management, enabling us to accurately reproduce your designs and ensure optimal printing results. Don't believe us? Request your free sample pack and judge for yourself!

Why Artron Printing excels in color management:

- Advanced Color Management System: Artron Printing employs state-of-the-art color management systems such as G7 color certification.

- Color Calibration: Artron Printing strictly calibrates printing equipment and processes to ensure output colors are consistent with design files.

- Color Matching: Artron Printing can achieve color matching across different substrates, meeting customers' requirements for color consistency.